当社3つの強み

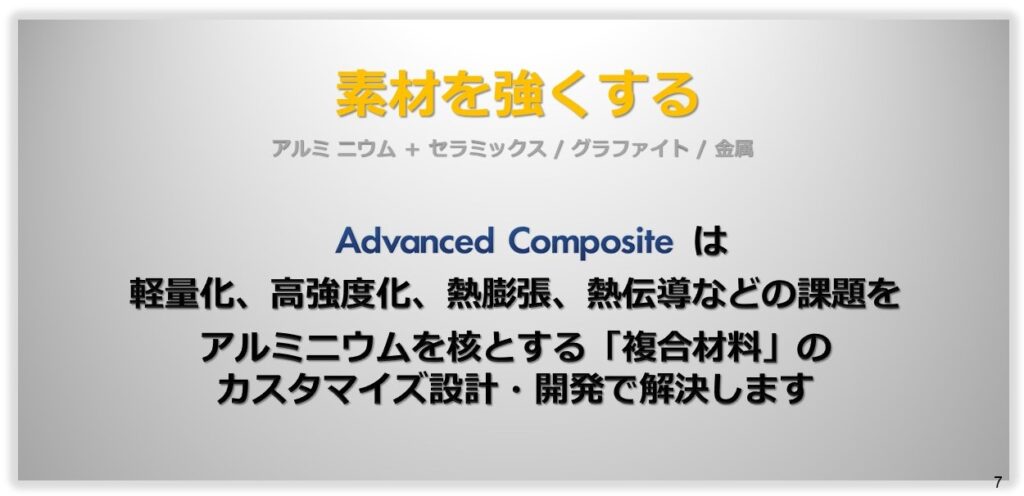

単一素材では達成できない特性や機能を

素材にデザインし飛躍的な特性の向上を実現する

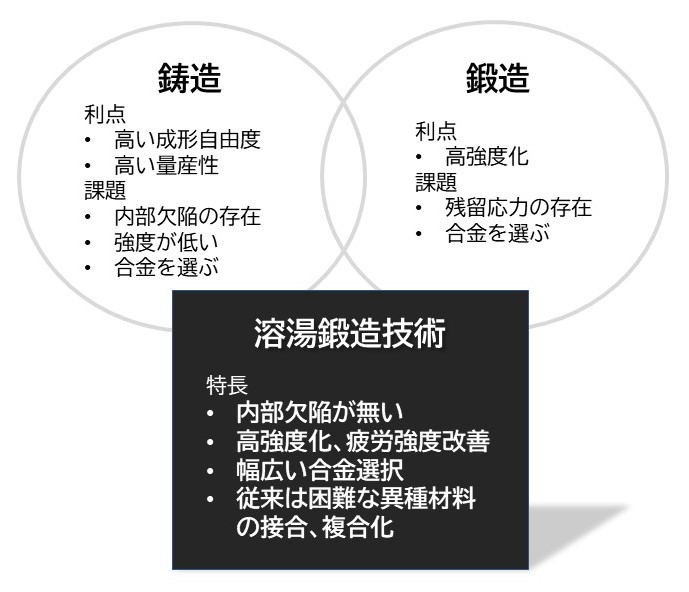

①世界トップクラスの溶湯鍛造技術

溶湯鍛造技術の経験とノウハウ

高機能化、接合、鋳ぐるみ、複合化

当社のコア・テクノロジーは「溶湯鍛造法」と呼ばれる高圧鋳造法です。溶湯鍛造技術とは従来の鍛造・鋳造では困難だった内部欠陥、強度、素材の制限といった課題を、高圧鋳造で解決することにより、内部欠陥の少ない素材や特性の優れた複合材料を鋳造する技術です。

当社の4つの応用技術

- 高機能化

- 接合

- 鋳ぐるみ

- 複合化

溶湯鍛造法により、単一素材及び他工法での複合材では得られなかったこれまでにない機能・物性・特性を持つ新材料を設計、製造することができます。

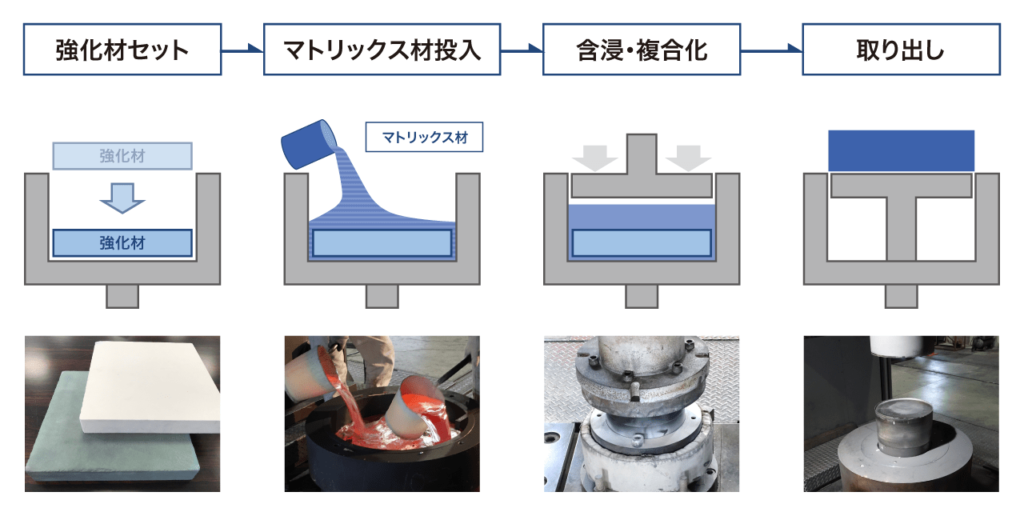

当社の金属基複合材料の製法 – 世界トップクラスの溶湯鍛造技術

当社の金属基複合材の製法

ー 世界トップクラスの溶湯鍛造技術

ー 世界トップクラスの溶湯鍛造技術

「強化材」に「マトリックス材(溶けた金属)」を供給し、高圧で含浸・複合化します。

単一材料および他工法での複合材料では得られない機能・物性・特性を付与することが可能になります。

強化材 (グラファイト/セラミック/金属)

- セラミック(アルミナ/炭化ケイ素/窒化ケイ素/ ホウ酸アルミニウム)

- 金属粉末( シリコンなど)

- グラファイト (等方性/異方性カーボンなど)

- 状態 (粒子・ウィスカー・短繊維・長繊維・多孔質体など)

マトリックス材(金属)

- アルミニウム(AC材・ADC材・展伸材)

- 銅・マグネシウム・ニッケルなど

②目的に合わせて素材の要求特性を実現する設計技術

これから成長する産業の未解決の課題に対して単一素材では達成できなかった様々な特性を有する金属基複合材料を設計できる

当社ではお客様の要望に合わせた材料設計を行っています。複合材は金属の代替材料としてだけでなく、そのメリットを十分に生かすため、強化材とマトリックス材の最適組合わせを選択し、配合比率を変えてユーザ-の要求に合わせて強度・剛性、熱膨張、熱伝導、剛性などの特性を達成する素材を提案できる手法を確立しています。

③アルミを中核とする金属基複合材製造の経験と実績

半導体製造装置部品などを金属基複合材で製造、販売

当社は他社に先駆けてアルミニウム基の様々な複合材料を実際に開発、製造、販売している数少ない企業です。加工性の良いAlbolonの開発, 他社に先駆けたグラファイトの複合材料など。