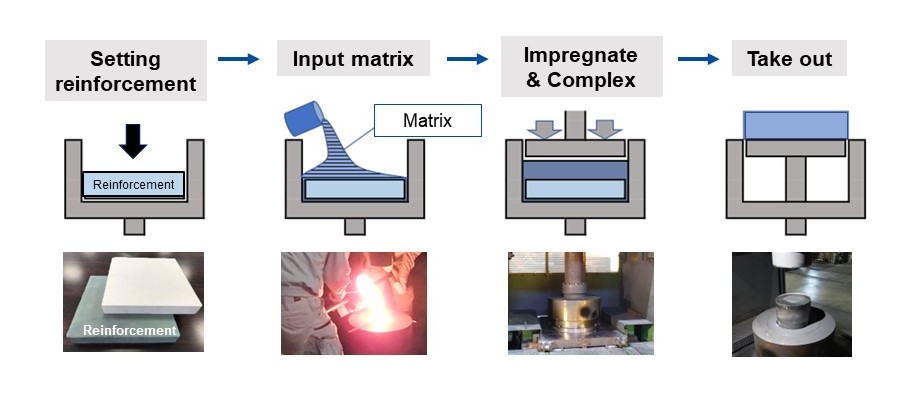

“Compositing” to create new materials by fusing dissimilar materials

・Materials with higher-performance, which cannot be achieved with single materials, are demanded.

・By combining multiple reinforcements with matrix metals, the composite materials realize a dramatic improvement in characteristics.

- “Ceramics (alumina/silicon carbide/silicon nitride/aluminum borate)

- Metal powder (silicon, etc.)

- Graphite (isotropic/anisotropic carbon, etc.)

- State (particle, whisker, short fiber, long fiber, porous body, etc.)

- “Aluminum (Cast alloys, Die-cast alloys, Wrought alloys)

- Copper, magnesium, nickel, etc.”

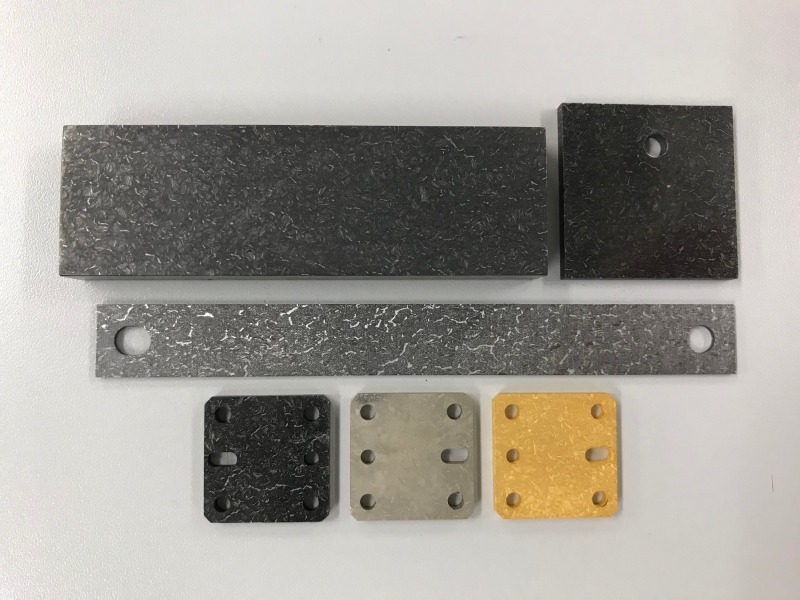

Our Metal Matrix Composite

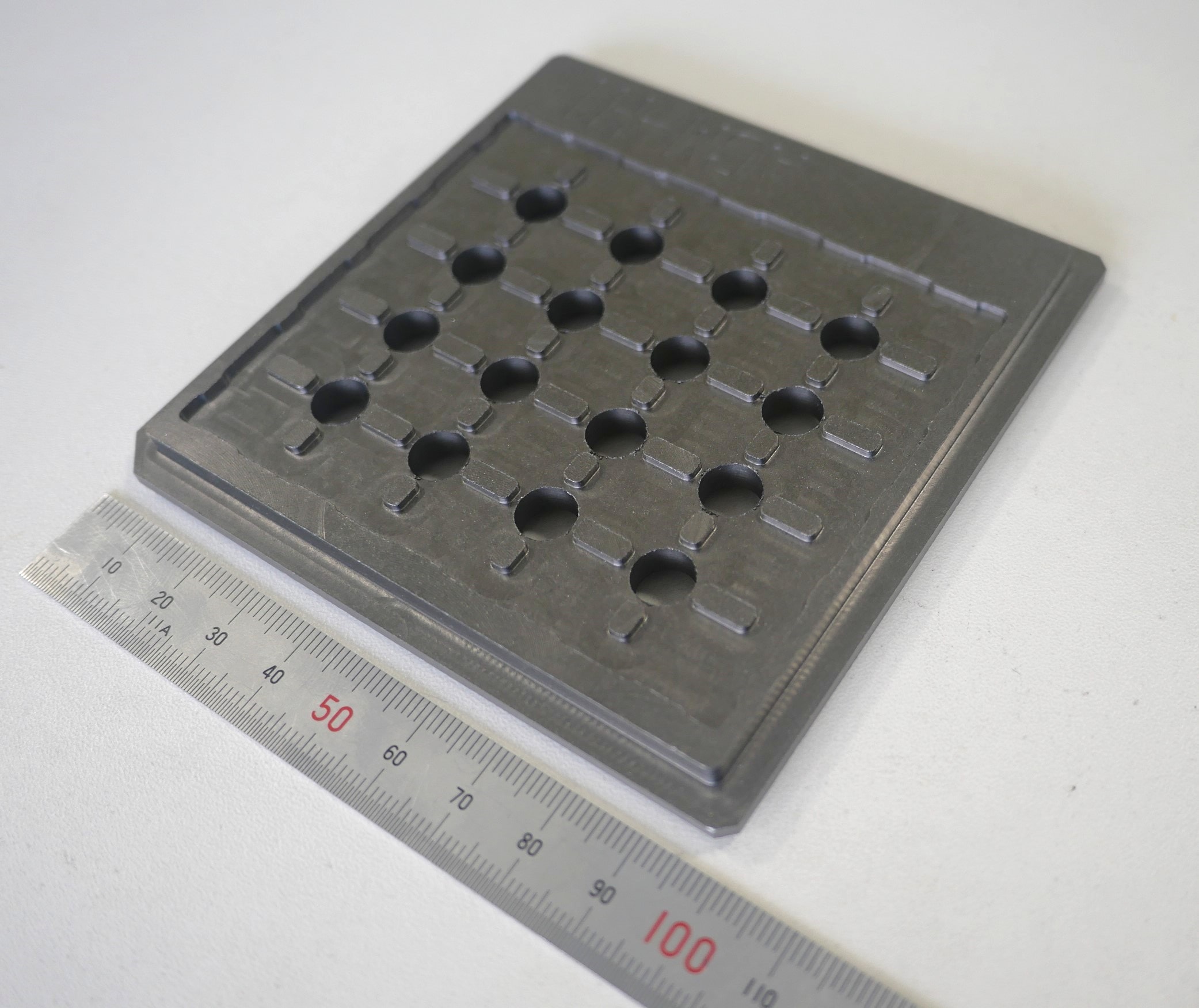

New ACM-H1 / H2

Overview

- Composite material of aluminum and graphite, an unprecedented new material

- A new material with a well-balanced characteristic value that has a thermal conductivity, which is second only to diamond, higher than silver and copper, and a small thermal expansion that is comparable to ceramics.

- It is also possible to arbitrarily design physical properties such as thermal conductivity, thermal expansion, strength, etc. according to the required needs.

Feature

- Thermal conductivity: 1.2 times the thermal conductivity of copper

- Coefficient of thermal expansion: Approximately 1/5 that of copper, as small as ceramics

- Strength (Bending strength): 2.5 times that of graphite

- Lightweight: Density less than 1/4 that of copper, less than aluminum

Application

- Alternative to aluminum and copper (heat spreaders)

- Thermal diffusion material for substrates: Ideal for heat spreaders for thermal diffusion as an alternative to Al-SiC, placed under ceramic substrates

New ACM-H3

Overview

- Composite material of aluminum and graphite, an unprecedented new material

- Rigidity is 123 GPa, higher than that of copper, and CTE (coefficient of thermal expansion) is about half that of copper.

- A new material that is superior to metal substrates made of aluminum and copper: Lighter than copper, stronger than aluminum, with a CTE comparable to that of titanium and a well-balanced thermal conductivity.

- Possible to design arbitrarily physical properties such as heat conduction, thermal expansion, strength, etc. according to the required needs.

Feature

- Lightness is 1/3 of copper, equivalent to aluminum

- Young’s modulus is 1.5 times that of aluminum

- Same thermal expansion as titanium: 8 ppm/K

- Thermal conductivity is better than pure aluminum: 256 W/m K

- Thermal conductivity, low thermal expansion, and small anisotropy

Application

- Alternative to aluminum or copper (Heat spreaders)

- High-rigidity heat dissipation structural members

(Sub heat spreaders, Heat spreaders, Heat sinks, etc.) - Materials with high rigidity suitable for in-vehicle use

New ACM-H4 / H5

Overview

- Unprecedented new materials: Aluminum and graphite composite material

- New materials with a balance of properties not found in conventional materials: high thermal conductivity comparable to ceramic/aluminum substrates, and low thermal expansion

- New materials with high strength and high Young’s modulus have potential for further applications beyond just heat dissipation materials.

- New materials with excellent machinability: Machinable with regular cutting tools.

Feature

- High thermal conductivity equivalent to ceramics / Al substrate

- High thermal expansion equivalent to ceramics /Al substrate

- Bending strength : more than twice that of graphite

- Excellent machinability: Machinable with high speed steel and carbide tools

- Physical properties such as heat conduction, thermal expansion, and strength can be designed to suit your needs.

Application

- Alternative to aluminum and copper (Heat spreaders)

- Heat diffusion material for substrates, placed under ceramic substrates to replace AlSiC

- Alternative to graphite, single piece heat dissipation low thermal expansion jig, available for large parts.

AC-Alox

Overview

- Composite material of aluminum / alumina

- As light as aluminum, Young’s modulus higher than cast iron

- Excellent mechanical damping

Feature

- Has been adopted in a vacuum environment

(medium vacuum 10⁻¹Pa or less) - Semiconductor manufacturing equipment cleaning Fluorine gas resistant

- Machining possible

- Easy surface treatment (electroless Ni plating, etc.)

Application

- Lifter pins for FPD manufacturing equipment

Reason for adoption: Fluorine gas resistant that does not damage glass - Movable stage for semiconductor measurement equipment

Reason for adoption: Light weight, high rigidity, excellent mechanical damping

AC-Albolon

Overview

- A composite material of ceramics and aluminum that is as light as an aluminum alloy and has a Young’s modulus and coefficient of thermal expansion comparable to cast iron.

- A new material that combines the “lightness” of aluminum with the “strength” of cast iron

Feature

- Light weight equivalent to aluminum

- Tensile strength, Young’s modulus, and coefficient of thermal expansion comparable to cast iron

- Machining is possible with carbide tools

- Light weight and high strength make it the ideal material for rotating bodies and high-speed moving parts.

Usage

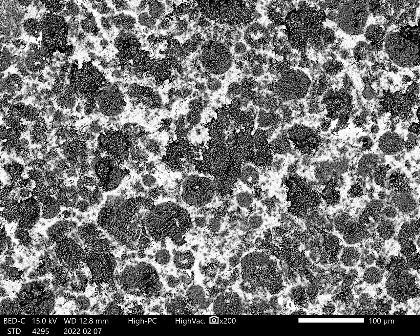

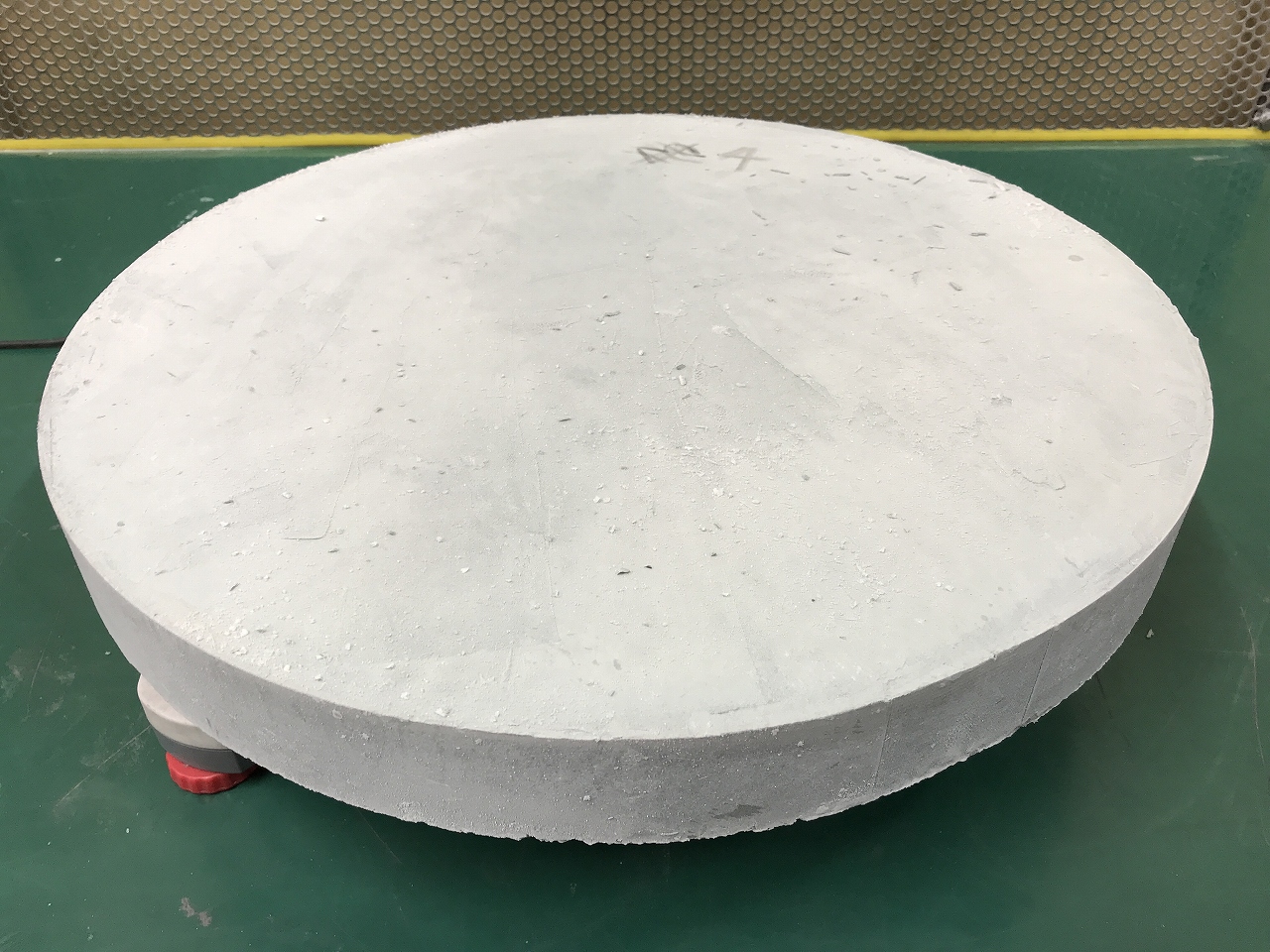

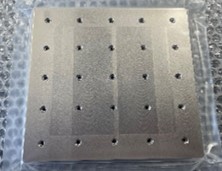

AC-Alsic

Overview

Composite material of SiC (silicon carbide) and aluminum. Its mechanical strength (especially rigidity/Young’s modulus) is particularly high, and its density is as light as aluminum, so it is characterized by extremely high specific rigidity (light weight and high rigidity).

Feature

- High rigidity with 1.8 times Young’s modulus, reduced thermal expansion to 2/3, and improved thermal

- conductivity compared to aluminum (A5052), the specific rigidity is 2.8 times higher and the thermal

- conductivity is 3 times higher compared to cast iron (FC250).

- Suppresses deformation and distortion caused by differences in thermal expansion.

- Thermal expansion coefficient close to that of stainless steel and carbon steel.

- Lower thermal expansion than aluminum and higher thermal conductivity than cast iron.

- Products are also available as ingots for gravity casting or gravity cast products (gravity and lost wax).

Usage

- Heat sinks, low thermal expansion machine parts

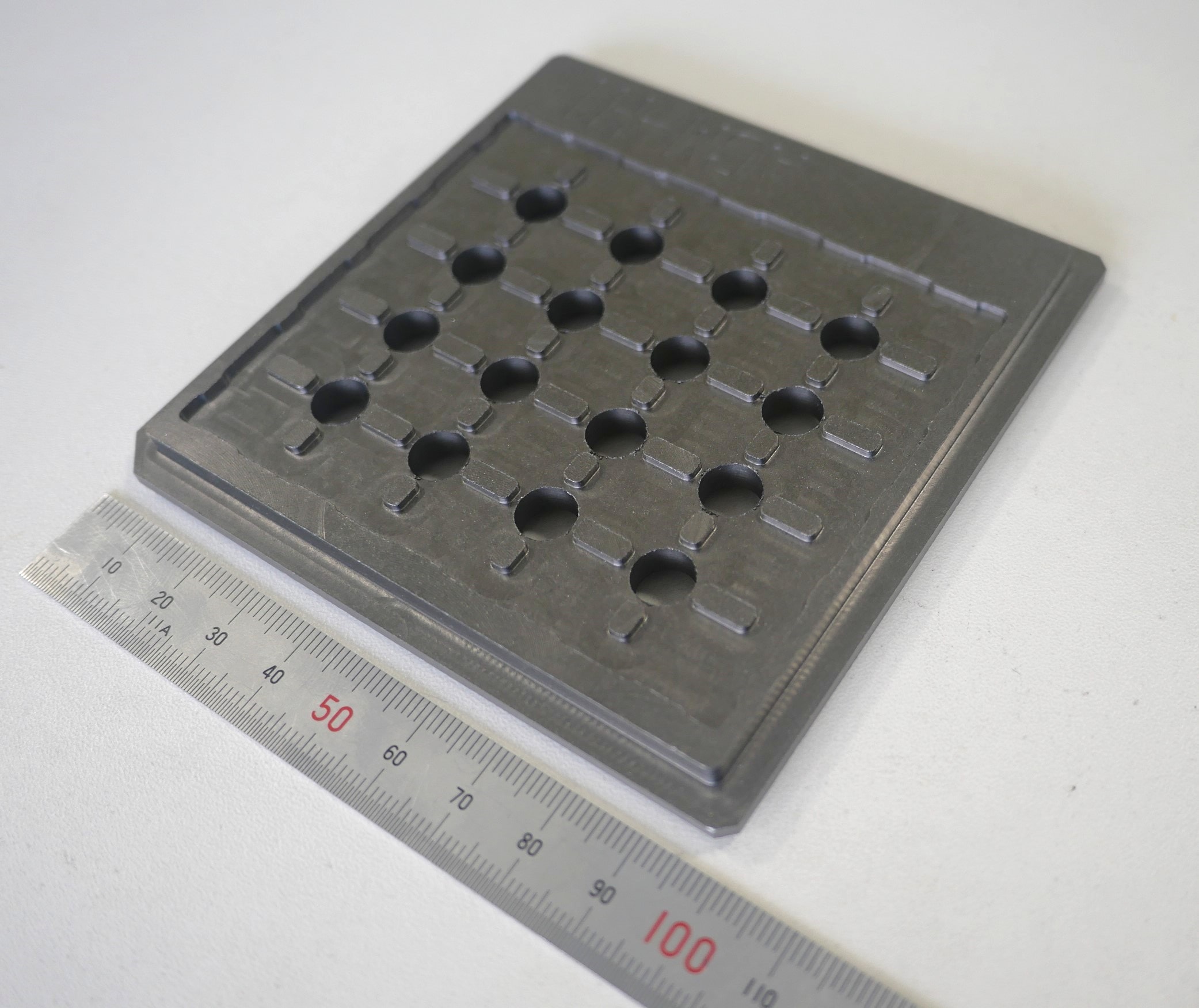

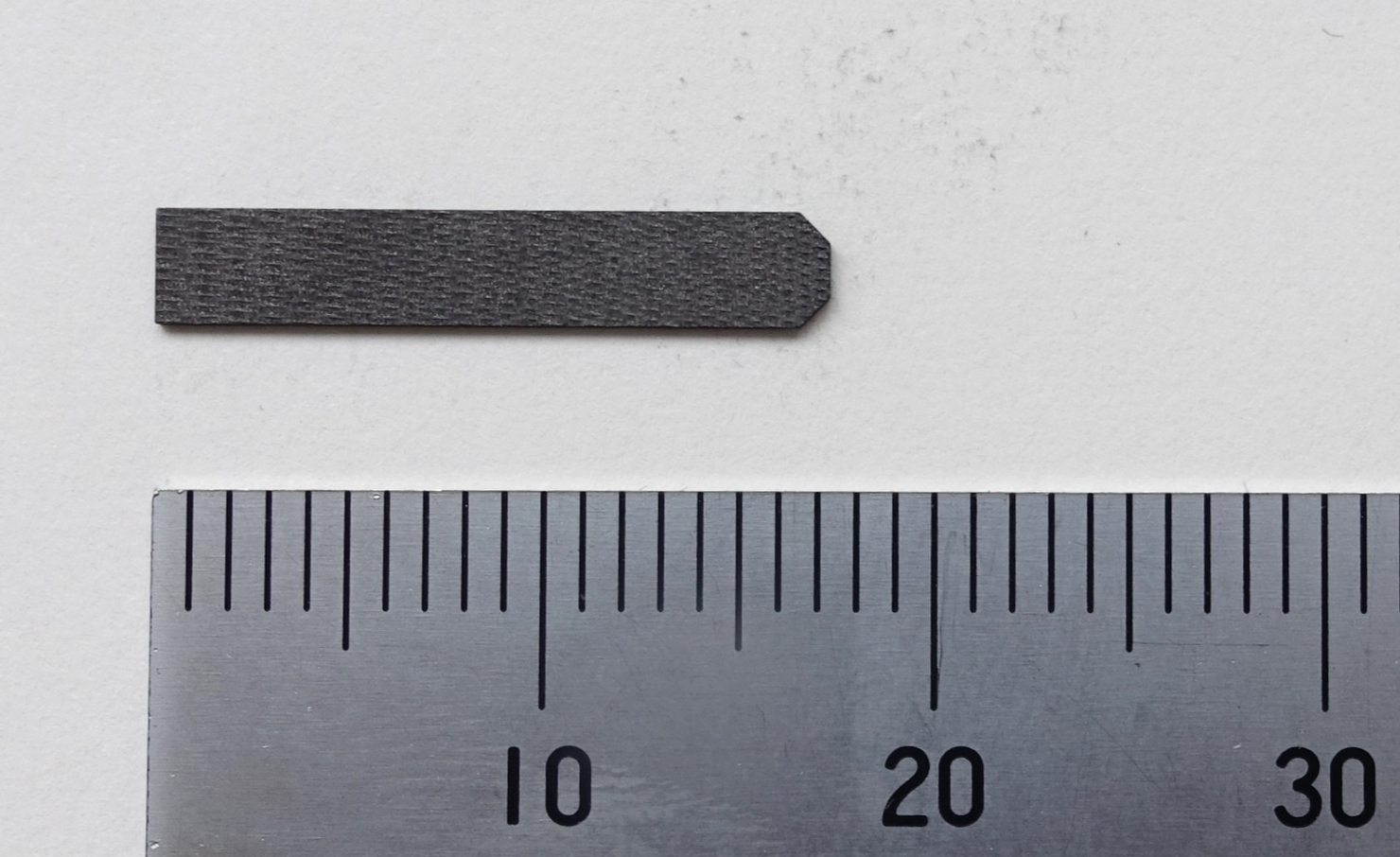

ACM-io

Overview

- A new material that carries heat with little deformation at high temperatures

- Composite material of graphite (CIP) and aluminum, which was considered difficult

- Its specific gravity is as light as graphite, and its coefficient of thermal expansion is as high as that of ceramics.

- In addition, the strength is improved compared to graphite, enabling finer machining and reducing dust generation.

Feature

- High thermal conductivity

- Low coefficient of linear expansion/thermal deformation

- Heat cycle resistance performance

- Lightweight as graphite

- Stronger than graphite

Optimal material for components that require high thermal conductivity and high dimensional accuracy at high temperatures. It is resistant to heat cycles and has a longer life than graphite by suppressing deterioration. Since surface treatment is possible, it is possible to significantly reduce dust generation compared to graphite.

用途

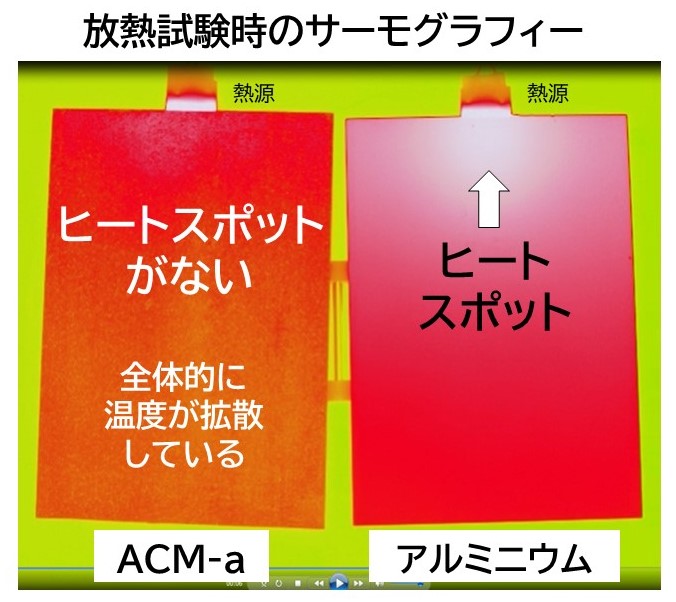

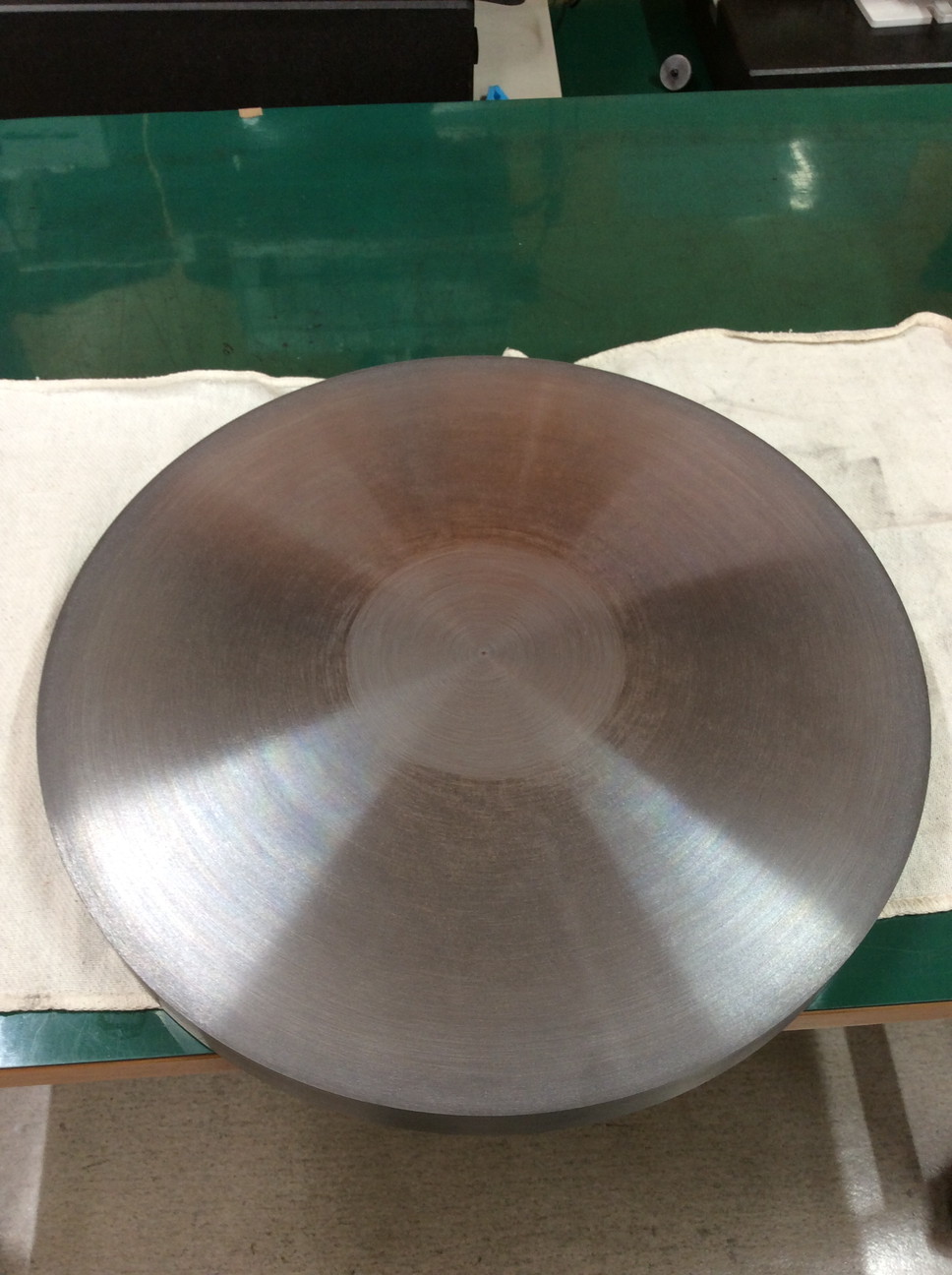

ACM-a

Overview

Composite material of graphite (extruded material) and aluminum, the specific gravity is as light as graphite, the coefficient of thermal expansion is the same as that of ceramics, and mainly enhances heat conduction and heat diffusion.

Feature

- Thermal diffusivity: 2.1 times that of copper, 2.7 times that of aluminum

- Coefficient of thermal expansion: about 1/2 that of copper, about 1/3 that of aluminum

- Density: less than 1/4 of copper

- Easy plating (nickel, gold, copper, etc.)

- Resistant to heat cycles

- Dissipates heat quickly into the material

- Quickly dissipate heat to the atmosphere

Usage

- Best material for heat management of computer, heat dissipation of LED, power device, and consumer electronics

- Replacement from copper and aluminum metal substrates (heat spreader)

- Heat sink for IGBT modules

AC-Alcon

Overview

Composite material of Si (silicon) and Al (aluminum), lighter than aluminum Machinable with carbide tools

Feature

- Specific Gravity: Lighter than Aluminum (2.45 g/cm3)

- Young’s modulus: same as cast iron (117GPa)

- Specific stiffness (Young’s modulus/specific gravity): Higher than Alsic (Sic 30%, Al 70%). 3 times higher than cast iron

- Coefficient of thermal expansion: Closer than the coefficient of thermal expansion of SUS guide

- Machinability: Machinable with carbide tools

- Vibration damping: excellent vibration damping

- No outgassing in a vacuum environment

Usage

- Front end of semiconductor manufacturing (lithography, inspection, etc)

- Back end of semiconductor manufacturing (chip mounting, bonding)

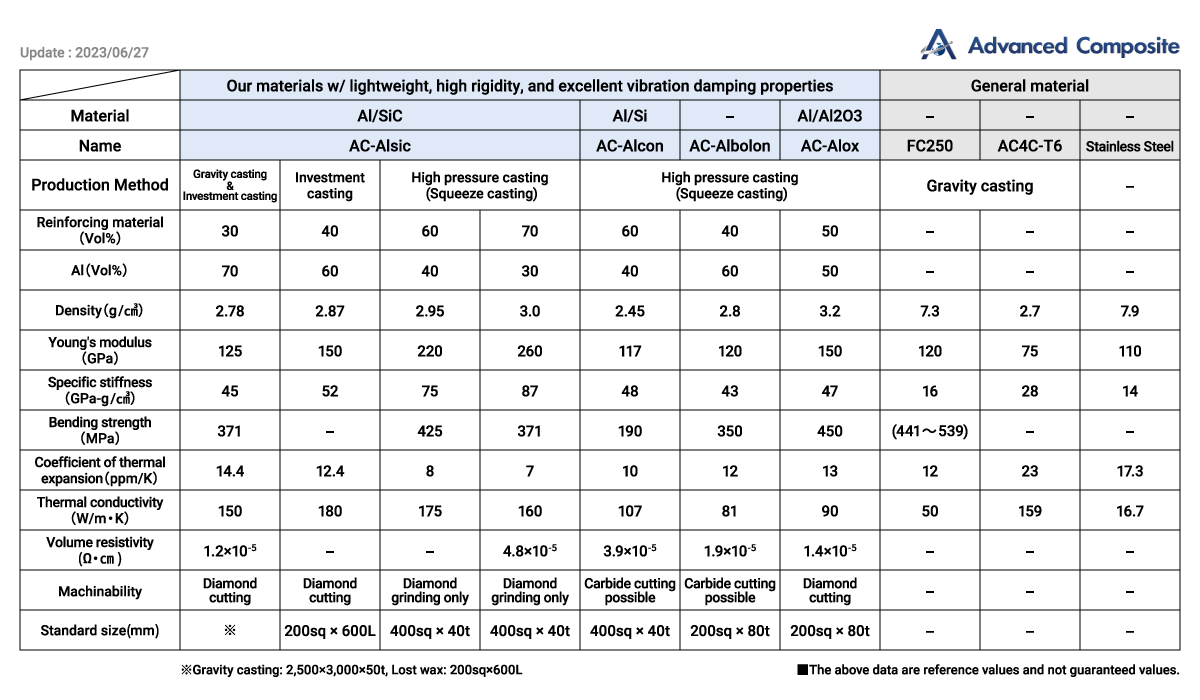

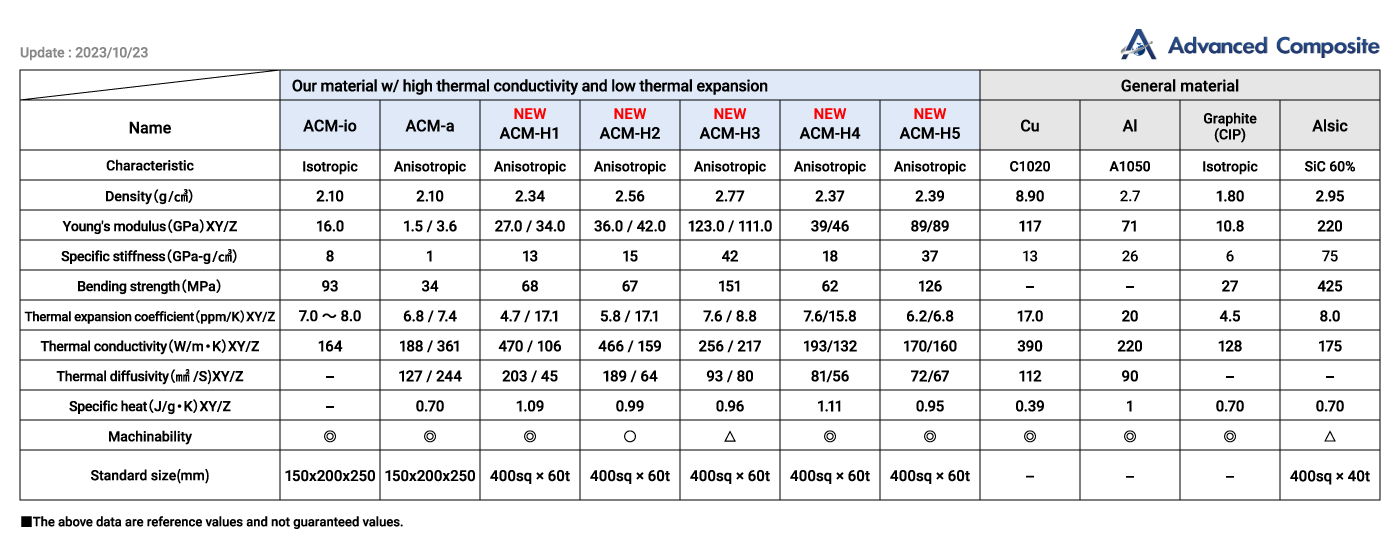

Material property comparison table

Our material w/ high thermal conductivity and low thermal expansion.

Our materials w/ lightweight, high rigidity, and excellent vibration damping properties.