In February 2023, the Ichimura Foundation for New Technology decided on 11 grantees for the 110th New Technology Development Grant, and Advanced Composite Co., Ltd. was selected as the grantee. The Ichimura Foundation for New Technology’s subsidies are aimed at the “practical application of creative new technology”, and are intended for development prototypes aimed at practical application after confirmation of basic technology is completed. We received a subsidy for research and development activities and practical application of our company’s

“Composite (MMC) consisting of ceramic powder, graphite powder and aluminum”.

Overview of new technology development subsidies

The Ichimura Foundation for New Technology develops creative research and new technologies in a wide range of science and technology, develops new fields of industry and science and technology in Japan, and contributes to the improvement of people’s lives by putting them into practical use. The purpose is that. Grant candidate themes that satisfy the application requirements are carefully and strictly selected and reviewed by the New Technology Development Grant Investigation Selection Committee and Examination Committee established at the Foundation, and are decided by the Board of Directors.

https://www.sgkz.or.jp/project/newtech/

We would like to once again thank everyone who cooperates with our research and development.

Since July 2015, we have been developing, manufacturing and selling metal matrix composite (MMC) materials and bonded products using the squeeze Casting method under the corporate philosophy of “contributing the future of the earth with materials”. In particular, through the development of new composite materials, we are striving to provide materials with optimal properties that could not be achieved with a single material, and to realize dramatic improvements in properties.

This grant has been a great help and a great encouragement for practical application. Various aluminum alloy-based composite materials manufactured by our squeeze casting method have characteristics such as light weight, high strength, high heat dissipation, low expansion, and easy workability. Optimal design is possible. By further advancing our composite material technology, we will continue to design and develop materials with new characteristics, aiming to innovate the world’s industries and contribute to the creation of a sustainable society.

About the Ichimura Foundation for New Technology

Since its establishment in 1968, the Ichimura Foundation for New Technology has been supporting research and development in science and technology, honoring outstanding science and technology, promoting international exchange, fostering creativity in science and technology, and supporting research related to plant growth. We are working to contribute to the development of Japan’s economy and society and the improvement of people’s lives by promoting science and technology through subsidies.

Our technology development details

“Composite (MMC) consisting of ceramic powder, graphite powder and aluminum”

Metal Matrix Composite (MMC) inherits the advantages of single metal materials, and combines them with recently developed high-performance single materials (ceramics, carbon, etc.) to provide properties that cannot be obtained with single metals or ceramics alone.

However, there are conflicts such as a decrease in yield due to sintered casting from the casting method used for manufacturing, and a high processing cost as a difficult-to-cut material because it is a high-strength material.

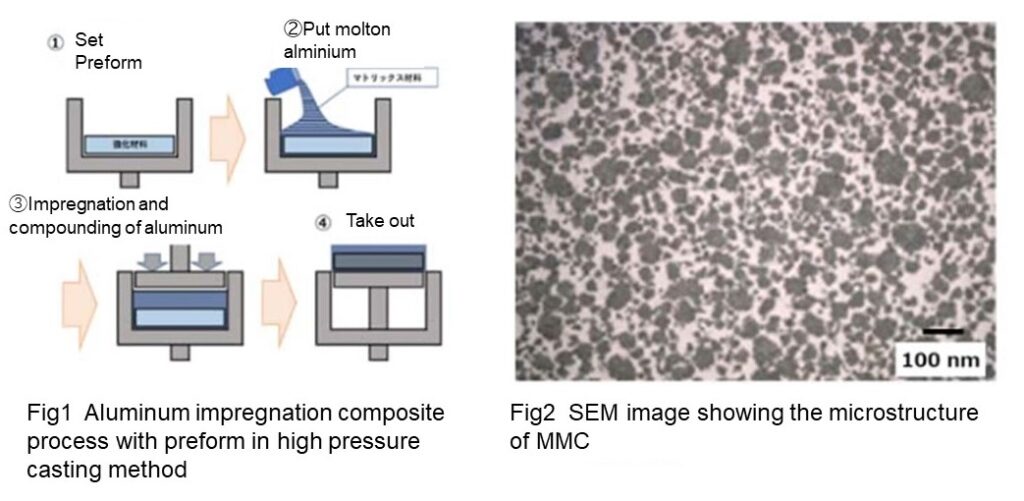

This technology creates a molded body (preform) made of mixed powder of a base material (aluminum) and functional materials (ceramics, carbon, etc.), and then impregnates it with molten aluminum under high pressure. It produces MMC with excellent machinability (Fig. 1). It is possible to obtain the desired physical properties by controlling the composition ratio of the final product and the interface structure between the base material and the functional material (Fig. 2) by adjusting the powder composition of the preform and the air gaps during preform formation. do. In particular, by including the aluminum powder of the base material in the preform, the control range of the composition ratio of the functional material and the base material is widened, making it possible to design the material according to the desired characteristics. In addition, the formation of a fine interfacial structure makes it possible to maintain the bulk strength of the MMC and ensure excellent workability because the functional material is fine. In this development, we aim to achieve the material quality (strength, thermal properties, workability) obtained from a test piece (φ60mm x 15mm) in a practical size (example: 310mm x 210mm x 95mm). is.

Compared to conventional MMC, the newly developed MMC is superior in controllability of properties and machinability, and is expected to significantly reduce manufacturing costs. First of all, there is a high possibility that it will be used as a basic material in the future.

Technology: Advance Composite Co., Ltd.

Developer: CTO Mutsuo Hayashi