Our Technology

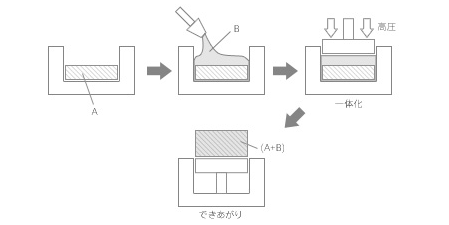

Composite by high pressure impregnation

Combine two or more materials by impregnation to make an ideal material with both properties.

For example,

- Metal-based Metal composite

- Carbon-based Metal Composite (CMC)

- Metal-based Ceramics Composite(MMC)

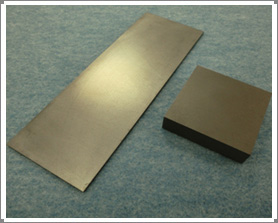

ACM-a ACM-io

ACM-a and ACM-io are carbon based aluminum composites with a volume ratio of more than 85% graphite impregnated with15% aluminum.

Generally speaking, compounding this combination has been described as "very difficult." This combination has become possible to manufacture by the "molten metal forging method" which is our core technology.

Since ACM-a has an extremely high thermal diffusivity and high thermal conductivity like copper, it also has excellent thermal emissivity. Also, since it has a low coefficient of thermal expansion like ceramics, it has a strong affinity with semiconductors and is excellent for "solder joint crack countermeasures."

As described above, for two main reasons, ACM-a is highly effective in "heat countermeasures."

In addition, ACM-a can keep many free electrons due to its high purity carbon crystal particles and scattered aluminum metal inside it, and it also has the effect of blocking certain radio waves.

Therefore, ACM-a can be said to be an indispensable new material for the next generation in the modern day, when the heat exhaust process has become more focused and important for the development of computers, LED lighting, power devices, home appliances, and more.

ACM-auses a non-oriented type of graphite as the base material. The added aluminum becomes a reinforcing material, and its strength (tensile and bending) is improved by about 20% compared to graphite alone. Also graphite has many gas pockets, which is a factor that impedes thermal conduction, but since aluminum blocks the holes, thermal conduction also improves. Also, as with ACM-a, it has a very low linear thermal expansion coefficient of 5 to 7, so it has the property of high dimensional accuracy in high temperature environments.

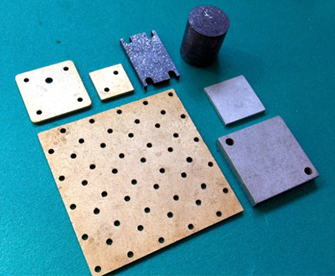

The above properties are suitable for high temperature environments and environments where dimensional accuracy or strength are required, such as positioning jigs for semiconductors, flow trays, and transport pallets. Therefore, they are well-received as replacement materials for existing graphite materials. In addition, this has better machinability than simple graphite, so it is suitable for mass production.

●Featured Property

- High thermal conductivity, similar to copper

- Higher thermal diffusivity than copper

- Lower coefficient of thermal expansion than copper.

7 ppm (similar to ceramics) - Lighter weight than aluminum 2.1 g / cm3

- Infrared reflection,

Radio wave blocking

AC-Albolon

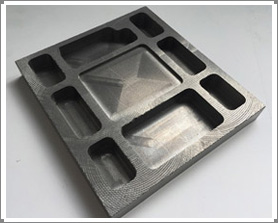

AC-Albolon is lightweight, has a high Young's modulus, and is an excellent material for cutting.

There were problems with the materials used for conventional robotic arms and XY tables.

For example, steel has inertia weight and is difficult to position for accuracy, aluminum alloy is lightweight but its Young's modulus is low and vibration occurs at high speed movement, or alumina sintered bodies are difficult to process and the processing cost is extremely high and it breaks easily etc.

We succeeded in solving these problems with our developed material “AC-Albolon”.

●Featured Property

- Lightweight

Mass is 1/3 of cast iron - High strength

High tensile strength and Young's modulus similar to cast iron - High Thermal resistance

Superior thermal resistance to that of aluminum alone by combining ceramics - Machinability

It is possible to machine with hard metal tools without using diamond tools

AC-AlSiC composite (aluminum + silicon carbide)

IIt is a composite material of SiC, which has hardness next to that of diamond and a high thermal conductivity, and aluminum.

Since it has a high thermal conductivity, high mechanical strength, and low coefficient of thermal expansion, it is suitable for substrates for high power devices or heat spreaders.

Also, the problem of difficult processability of SiC can be solved by providing an aluminum layer on the surface.

●Featured Property

- Lightweight

- High rigidity

- High thermal conductivity

- Low thermal expansion

- Friction resistance

AC-Alox

We impregnated alumina short fiber with A1050 aluminum.

This has more than double the tensile strength compared to A1050 alone, and the toughness is also greatly improved (compared to integration of the tensile strength curve).

It is also suitable for small structures due to its light weight, high strength and high toughness.

It is good to use for parts such as heaters, as the strength does not decrease in a thermal (~ 200 ° C) environment.

We use it for insert-casted heaters for semiconductor manufacturing equipment.

Also we can change the aluminum matrix, such as A5052 (improved strength and processability) and AC3A (for complex shaped products) according to the application and purpose.

●Featured Property

- Higher strength than simple aluminum

- Excellent dimensional stability at high temperatures

- Excellent processability

- Changeable aluminum matrix