Product

Parts for Shinkansen bullet train air brake system compressor

Material: Aluminum (AC8A) Technology: Technological advance by high pressure casting

●Description

A spiral-wound compressor is mounted on Shinkansen or express trains as an air source for air brakes.

Our spiral swirling body, which is the main component of our system, is the largest in the world (300mm diameter).

●Featured Properties

- Fatigue strength comparable to extension material

- Strong against vibration, hard to crack

The above characteristics are extremely suitable for brake compressors where reliability is important.

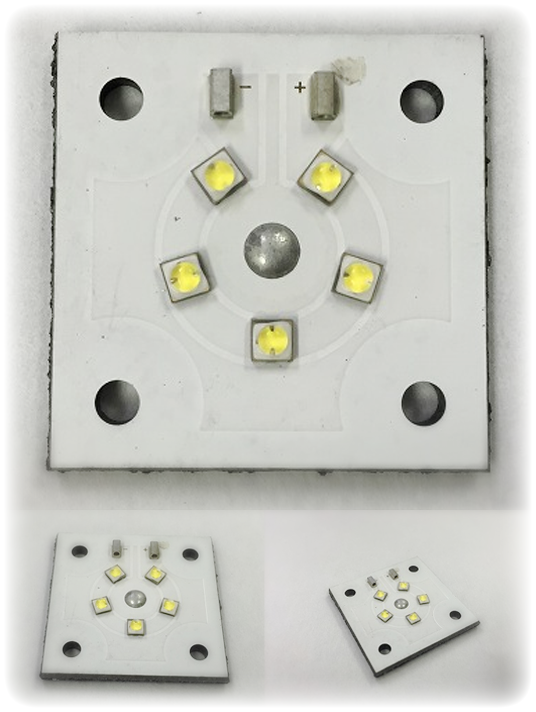

LED substrate module

Material: ACM-a

●Description

In general, LED lighting is said to have a long life, but in fact, the life of catalog values could not be guaranteed.

This is because the problem of heat generated from the LED chip causes various problems such as a decrease in the life of the chip itself, deterioration of the resin due to heat, and a failure from a crack due to the heat cycle.

We solved these thermal problems with the new heat dissipation material “ACM-a” and “Heat Bridge Structure”.

These two new technologies have made it possible to quickly transfer the heat of the LED to the heat sink, ensuring the LED's inherent long life.

Kandenko adopted this new technology for LED lighting equipment for high ceilings, and received the Encouragement Prize from the “JFCA FAIR 2015” sponsored by the Nippon Electric Construction Industry Association.

This material has also been adopted in factories with severe conditions, such as factories that have melting furnaces and high temperatures near the ceiling, and factories with constant vibration caused by presses.

●Featured Properties

- Excellent thermal conductivity and diffusivity

→ Excellent exhaust heat and long life of LED chip - Thermal expansion coefficient equal to LED chip

→ No trouble due to solder cracks

●Application

Heat dissipation substrate module for LED

LED lighting equipment for high ceilings (high-powered LED)

●Description

・From the W results, an extremely heat-resistant LED substrate was realized.

#1 1. ACM-a, a new material with excellent heat dissipation was adopted.

#2 2. Adopted a new technology heat bridge structure.

・From a careful CFD simulation, an aluminum chassis and an aluminum radiation fin with a structure that has excellent exhaust heat was realized.

・Improved the luminous efficiency by devising the arrangement of the LED chip, achieving an equipment efficiency of 110 (lm / W) or more and a weight of 4.0 (kg).

・Achieved the same floor illumination with 1/4 the power of a 400 W mercury lamp.

This LED lighting is for high ceilings, which adopted the new heat dissipation material ACM-a developed by our company for LED modules. ACM-a has solved the "thermal problem" which is a major obstacle for the spread of LED lighting.

●Featured Properties

- Light distribution similar to a mercury lamp

- Energy saving

- High durability (environmental temperature -30 to 60°C)

- Lightweight

Solar powered white LED street light

Material: ACM-a (Adopted for LED module) / Technology:Composite

●Technology:Composite

Solar Powered White LED Street Light is an outdoor lighting system that realizes the elimination of the need for dead bulb replacement work or an external power supply, by combining solar panels, storage batteries and white LED lighting.

It turns on automatically after sunset and turns off automatically after a set time.

For normal use, it lights up at an energy saving luminance, and brightens at a rated luminance for about 15 seconds when a body is detected by the detection sensor.

●Featured Properties

ACM-a, developed by our company, is used for LED modules, so it is more resistant to brightness and temperature differences than incandescent and fluorescent lamps of the same wattage, and there is no lighting failure due to solder cracks.IGBT mounting jig components - Positioning tray

Material : ACM-i

●Description

A feature of ACM-i manufactured by our company as a material to replace graphite jigs is that it is easier to handle than graphite.

Features such as less dust generation, possible to plate, and a higher strength than graphite, significantly eliminate graphite handling defects.

In addition, there is the benefit that being light weight, dimensional error does not occur even if heat is applied because the thermal expansion coefficient is lower than SUS etc.

●Featured Properties

- Low coefficient of thermal expansion, less likely to cause dimensional errors

- Less dust generation than alternative graphite alone

- Ni-P plating is possible, which is difficult for graphite

●Application

Alignment tray for loading products into oven Assumed to be left for up to 6 hours in an oven at about 200°C

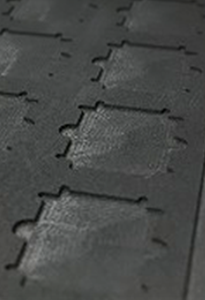

IGBT mounting jig components - Positioning tray for semiconductor

Material : ACM-i

●Description

A feature of our ACM-i as a material to replace the graphite jig is that it is easier to handle than graphite.

Features such as less dust generation, possible to plate, and a higher strength than graphite, significantly eliminate graphite handling defects.

In addition, there is the benefit that being light weight, dimensional error does not occur even if heat is applied because the thermal expansion coefficient is lower than SUS etc

●Featured Properties

- Low coefficient of thermal expansion, less likely to cause dimensional errors

- Less dust generation than alternative graphite alone

- Lightweight

- It is stronger than graphite alone and less likely to chip

●Application

Semiconductor positioning jig

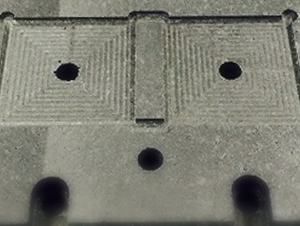

IGBT mounting jig parts - Positioning frame for semiconductor

Material : ACM-i

●Description

The main features of our ACM-i as a material to replace jigs made of graphite and copper are "high heat dissipation" and "low coefficient of thermal expansion".

Features such as less dust generation, possible to plate, and a higher strength than graphite, significantly eliminate graphite handling defects.

Since it has similar thermal conductivity as copper, and a higher thermal diffusivity than copper, it also has excellent heat dissipation characteristics

●Featured Properties

- Low coefficient of thermal expansion, less likely to cause dimensional errors

- High thermal conductivity and excellent heat dissipation

- Lightweight compared to copper, which is one of the alternatives

- It is stronger than the alternative graphite alone and less likely to chip

●Application

Jig for semiconductor positioning Measurement jig

Measuring jig Heat sink shape

Material : ACM-a + Ni-P plating + Au plating

●Description

ACM-a has better thermal conductivity than graphite and higher emissivity than metals such as aluminum, so it has a high ability to release heat from the fins into the air, making it an ideal heat sink structure.

It is also has a low coefficient of thermal expansion and is less likely to cause dimensional errors, so dust generation is minimal, making the material extremely easy to process.

●Featured Properties

- High thermal conductivity, high heat dissipation performance of the fin section

- Low coefficient of thermal expansion, less likely to cause dimensional errors

- Less dust generation than alternative graphite alone

- Gold plating possible, good wettability

●Application

Jig for measuring semiconductors

Positioning table for bonding equipment

Material : Aluminum (ADC12)+Al+9Al2O52B2O3 / Technology: Composite

●Description

The materials used in robot hands and XY tables in the past were mainly iron alloys and aluminum alloys, and in particular those that require high Young's modulus included alumina sintered products.

Iron alloys have a relatively high Young's modulus, but they have a large specific gravity, so the inertia force works to move at a high speed, which places a burden on the position accuracy and the motor.

Aluminum alloy is lightweight, but its Young's modulus is small, and vibration occurs at high-speed movement, resulting in poor position accuracy.

Therefore, sintered alumina products have come to be widely used because of their high Young's modulus and relatively low specific gravity.

However, sintered alumina products are extremely difficult-to-process materials, require high mechanical costs, and are extremely delicate materials that are easily broken.

In order to solve the above problems, we have developed a composite of Al + 9Al 2 O 52 B 2 O 3 and an aluminum alloy (A Al + 9 Al 2 O 52 B 2 O 3).

A Al + 9Al2O52B2O3 is an excellent alternative to existing materials because it has a high Young's modulus, a low specific gravity, and is easy to process.

●Featured Properties

- Lightweight compared to cast iron / High Young's modulus

- Excellent machinability

●Application

Fields that move at high speed and have high positioning accuracy

├ Robot hand

├ X-Y table

└ Dividing plate such as a chip mounter