Our Technology

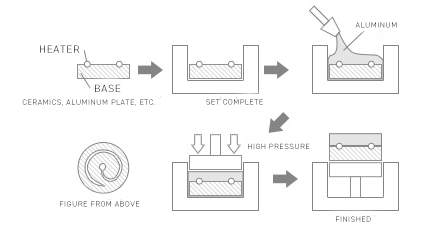

Insert-casting by high pressure casting method

Long-life insert-casting heater with few blowholes, excellent heat conductivity and excellent temperature uniformity (Since insert-casting heater can minimize outgassing, it is suitable for semiconductor manufacturing equipment.) We succeeded in developing a heater with higher temperature specifications by combining it with ceramics. (Low thermal expansion rate & excellent dimensional stability)

Insert-casting heater wire (SUS, Inconel, etc.) in aluminum

Conventional insert-casted heaters had blowholes which interrupted heat conduction from the heater wires and made temperature uniformity worse.

Therefore the heater wire tended to heat up easily and needless strain was placed on it, resulting in the shortening of the heater wire’s life.

Also, since the conventional insert-casted heater had blowholes and caused outgassing, we could not use it in a vacuum atmosphere such as in a semiconductor or liquid crystal manufacturing equipment.

Since the heater body was made by aluminum alloy, the thermal expansion rate was high. Therefore it was unsuitable for use in situations with importance on the dimensional stability of the heater. In addition, using temperatures more than 200℃ decreased the stiffness and dimensional stability, so a conventional insert-casted heater used only a narrow temperature range.

We could develop a long-life heater with very few blowholes, excellent heat conductivity and outgassing-free by using the molten metal forging process.

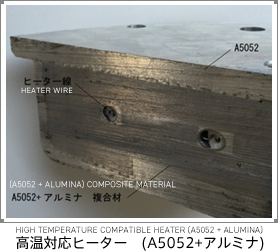

We also developed a heater that can be used within a 350℃~400℃ temperature range by insert-casting (combining) ceramics as a reinforcing material.

By using ceramics as the reinforcing material, the thermal expansion rate of the heater can be decreased, and dimensional stability can be ensured. Therefore our heater finds a fit in many applications such as semiconductors (for film formation, etching and ashing) and insert-casted heaters for liquid crystal film formation.

Featured property:

- Excellent temperature uniformity, No deformation in high temperatures (400℃), Outgassing-free Long-life