Our Technology

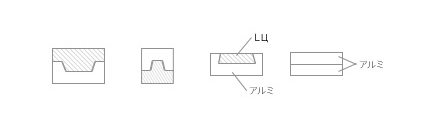

Joining by high pressure press

We succeeded in crimping dissimilar metals or homogeneous metals together by high temperature and high pressure in the forging cast process.

Since the joint surface is alloyed like diffusion bonding, the strength and heat conductivity have been greatly improved compared to the standard joining method.

For example

・Near-net joining of copper and aluminum

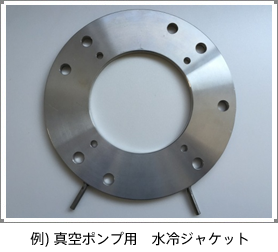

・Joining water-cooled tube with two aluminum plates

Joining SUS tube by sandwiching it in-between two aluminum plates

We succeeded in joining stainless steel pipes by sandwiching it in-between two aluminum plates.

We developed an excellent water cooling plate with high adhesion, high pipe cooling performance, and low heat accumulation.

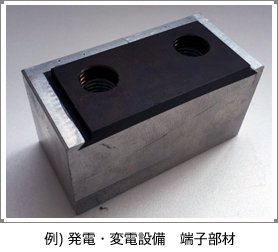

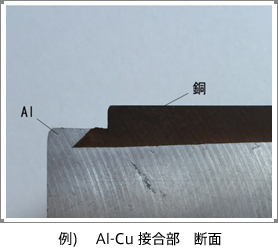

Joining of aluminum and copper

We succeeded in joining copper and aluminum.

Copper can serve as an IHS (Integrated Heat Spreader) and aluminum (Al) can conform to each component through easy processing.

This joined body can be applied to Heat-sink.

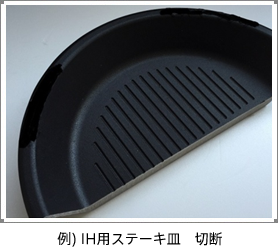

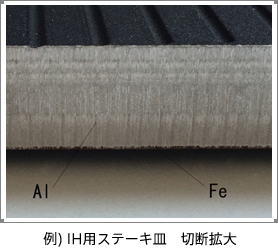

Joining of aluminum and iron

It is a cooking utensil for IH.

Basically, cooking utensils for IH cannot be utilized unless they are made of magnetic material such as iron.

However, iron cooking utensils were heavy and hard to handle.

Then we succeeded in joining a thin steel plate to the bottom of a light aluminum pan with our joining technology.

In addition, since aluminum has better heat conductivity than iron, heat spreads throughout the whole cooking utensil quickly and food can be cooked faster and more evenly.

Therefore, food can be made deliciously and quickly.