Our Technology

High-performance metal by high pressure casting

Originally, molten metal forging is a technique to improve the properties of aluminum alloy.

Using this molten metal forging technique, we developed a technology to make composite materials by impregnating the preform with aluminum at high pressure.

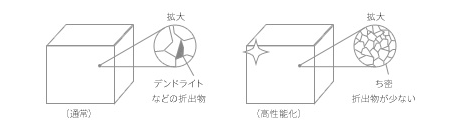

Effect:

- Internal defects can be reduced

- Fatigue property is better than casting (Near the lower limit of bending materials)

- Structural refinement

ADC14

ADC14 is a favored material for its mechanical strength resistance against friction. In particular, its mechanical strength at high temperature is excellent. Hyper Silumin alloys, including ADC14, are in general hard to cast in the mold. Our process enables ADC14 to get the fine tissue.

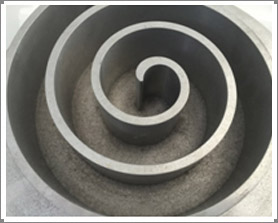

●Example of shape (piston sleeve)

●Featured property

- High mechanical strength・High friction resistance

- Low coefficient of thermal expansion

- Excellent mechanical strength at high temperature

- Aluminum for die casting but it is possible to cast with the molten metal forging method

AC8A

AC8A is the casting –grade aluminum alloy which has low coefficient, and its alloy composition is Al-Si-Cu-Ni-Mg, and it has good resistance against high temperature and friction.

It is used for compressors, pistons for heat engines, pulleys and bearings.

This is a highly durable and reliable material that has few fatigue cracks due to the effects of the high pressure casting methods..

It has a tensile strength of about 10% or more compared to general AC8A.

●Featured Property

- 10% increase in tensile strength

(compared to AC8A in general) - High endurance

- Strong against vibration

- Few blowholes