Our Technology

Core Technology

The Molten Metal Forging Method

The molten metal forging method is a high-pressure casting method, a way in which molten metal is put into a cast and applied to high pressure in order to make an alloy with excellent properties. It is also suitable for producing composite materials by preform impregnation, joining with solid dissimilar metals, and manufacturing castings such as heaters.

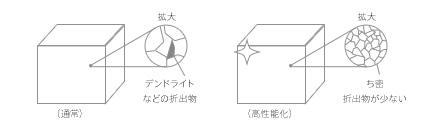

In this casting method, since the molten metal is solidified in a relatively short time, it is possible to produce a cast with a fine alloy structure, few blowholes, and improved strength properties and reliability. It also has a property of high fatigue strength compared to wrought products. (Note1)

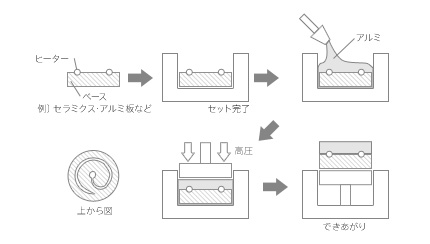

The manufacturing of MMC(Note 2), a composite material impregnated with metal for preforms such as ceramics, is our company’s molten metal forging technology's strong point. In order to produce a good quality MMC, it is necessary to impregnate and complex metal in a preform (Note 3) quickly without generating any compound. Our molten metal forging method is a very effective casting method, as it can solidify the molten metal in a short time, and it is possible to impregnate the metal uniformly in the preform.

Molding at high pressure and high temperature, which is a property of the molten metal forging method, is also excellent in joining solid metals and in the casting of precision high-temperature heaters where outgassing is a concern.

The molten metals are representatively aluminum, copper and magnesium. We mainly handle aluminum. Among them, we use A1050, A5052, A6063, AC3A, AC8A, ADC12, ADC14, or in-house adjustment aluminums etc., are used. It is also possible to make a proposal upon customer request.

Our molten metal forging method is the world's top casting method, and all the excellent materials we produce are produced by this molten metal forging method.

(Note 1)Wrought products: A kind of aluminum alloy material, which is a generic name for extrusion, rolling and forging.

(Note 2)A generic name for metal based composite materials.(Metal Matrix Composite)

(Note 3)Preform ··· Reinforced material with fibers, particles, etc. that are previously molded so that the dissolved metal can easily penetrate it.

●Featured property of the Molten Metal Forging Method

- High tensile strength

- Few blowholes

- High fatigue strength (Defect miniaturization such as porosity)

- Extremely small variations in individuals

- Fine metal structure

- Unlimited alloy types

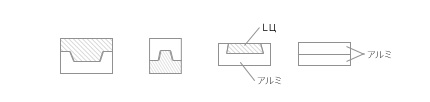

-What becomes possible by the molten metal forging method is…

-

#1 High performance metal

Originally, molten metal forging is a technique to make aluminum alloys with better qualities. Using this molten metal forging technique, we developed a technology to make composite materials by impregnating the preform with aluminum at high pressure.

・Internal defects can be reduced

・Fatigue property is better than casting (Near the lower limit of bending materials)

・Structural refinement

-

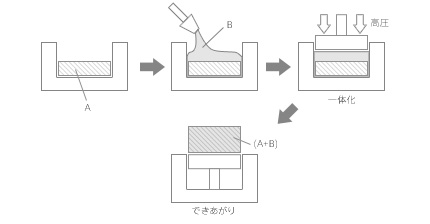

#2 ② Producing composite metals by impregnation (Preparation)

Combine two or more materials by impregnation to make an ideal material with both properties

For example,

・Metal-based metal composite (Metal Matrix Metal Composite)

・Carbon-based Metal Composite (CMC) (Carbon Matrix Metal Composite)

・Metal Matrix Composite

-

#3 Casting

Long-life insert casting heater with few blowholes and excellent heat conductivity and temperature uniformity (Suitable for semiconductor manufacturing equipment because generation of outgassing can be minimized) Realization of high temperature heater specification by combining with ceramics (Small coefficient of thermal expansion, excellent in dimensional stability)

-

#4 Joining

Crimping dissimilar metals or same metals with high temperature and high pressure via the molten metal forging method.

The joining surface is alloyed like diffusion joining, so the strength and heat conductivity are greatly improved compared to the normal joining method.

For example:-

・Near net joining of copper and aluminum

・Joining a water-cooled tube with two aluminum plates