Research data about our company’s techniques

1.LED lighting equipment for high ceilings (high powered LED)

■Features of our LED lighting which uses our material, ACM-a, solves the “thermal problem”!!

By adopting ACM-a as a heat dissipation substrate module for LED modules, LED chips are prevented from getting hot, as well as preventing solder cracks.

(Energy Saving & Highly Efficient)

- To make the equipment more efficient than other companies, it has low power consumption and is bright

- Power consumption: 109 [W] (same or higher than other companies)

- Power consumption: 109. Equipment efficiency: 102 [lm / W]

[Long life]

- Adopting new material ACM-a for LED substrate

- Adopts a new technology heat bridge structure, and clears the “thermal problem” significantly.

- ・Exhaust heat problem clear

- ・No solder cracks

[Light weight]

- Lighter than other companies. Weight 6.3 kg

[Mercury lamp 400 W substitute]

- A lighting arrangement design equivalent to a 400 W mercury lamp is possible.

- Wide angle light distribution.

■Provided Data from Environmental Test Results: Kandenko Corp.

By adopting "ACM-a" for the heat dissipation substrate module, the “thermal problem” mentioned above was solved. Our LED lighting is highly reliable to withstand high-load environments.

Environmental temperature -30°C 15,000 times turned on and off Environmental temperature + 60°C 1,000 hours

Continuous lighting * In the case of a typical aluminum substrate under the same conditions

500 to 2000 times turned off and on continuous lighting for 200 hours

The illumination did not drop even after the test.

The illumination does not drop at all even after the test!!

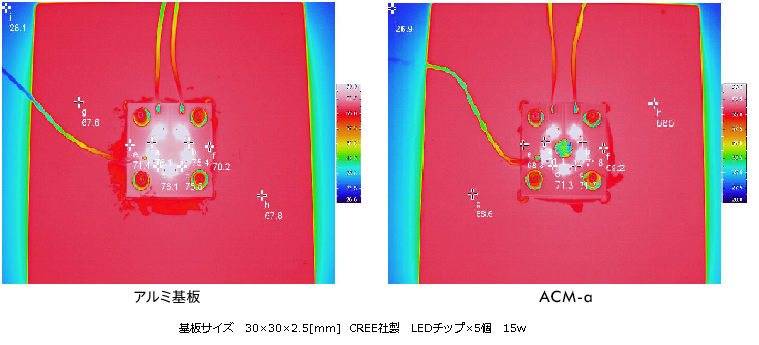

■Heat dissipation comparison of ACM-a and aluminum~LED Module~

2 kinds of LED modules were made (ACM-a, aluminum), driven with the same force, and were observed with thermal imaging after saturation.

*The size of the heat sink installed under the LED modules are both (100 x 100 x 45 mm). It can be seen that the temperature of the chip and its surrounding area is higher with the aluminum substrate than with the ACM-a substrate.

The ACM-a substrate quickly transfers the heat generated from the LED chip to the heat sink, so the chip area is not as hot as the aluminum substrate.

Lowering the temperature of the LED chip is a characteristic that greatly extends the product life.

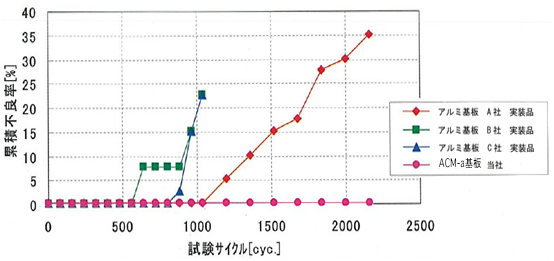

■Heat cycle test

These are the results of a heat cycle test between our ACM-a substrate and other companies' aluminum substrates.

With other companies' aluminum substrates, the defect rate rose between 600 to 1000 cycles, but the defect rate for ACM-a was 0 even after 2000 cycles.

■Image of Common LED Lighting

The LED chip itself, which turns electricity into direct light, has considerable heat

The heat stroke causes damage to the chip and surrounding circuits, causing the brightness to decrease and eventually go out.

Mr. Jake Daison

2.ACM-a

. ACM-a ACM-a (left) vs. Aluminum (right) Heat Dissipation Comparison

※The video has reduced 10 minutes to 10 seconds

1. Purpose

Heat dissipation comparison of ACM-a and aluminum.

2. Result

・ACM-a was able to keep the temperature of the heat source lower than that of aluminum.

(The heat source section of aluminum is more white→ higher temperature)

・ When the current of the heat source was turned off, the temperature of ACM-a decreased in a shorter time compared to aluminum.

3. Conditions

Comparative sample Left: ACM-a Right: Aluminum

Sample size 185 × 140 × 2.5 mm

Heat source 20w rubber heater (Made by Sakaguchi Electric)

Measurement time 10 minutes

Room temperature 22 degrees